WORK PROCESS

Our Primary Product Lines

- Screw Air Compressor

- Air Compressor

- Desiccant Air Dryer

Adhering to the concept of quality first and customer foremost, HP will provide you perfect and reliable pre-sales and after- sales services.

Our professional designs and technologies will create a perfect image to impress you customers, and our cost-effective products will bring huge profits to you.

Application fields

Air compressors can be seen in a wide array of manufacturing. textiles, building materials ,steel, non ferrous metallurgy, petrochemical , food and beverage, electronics, energy, pharmaceutical, shipbuilding, mining, light industry, and military.

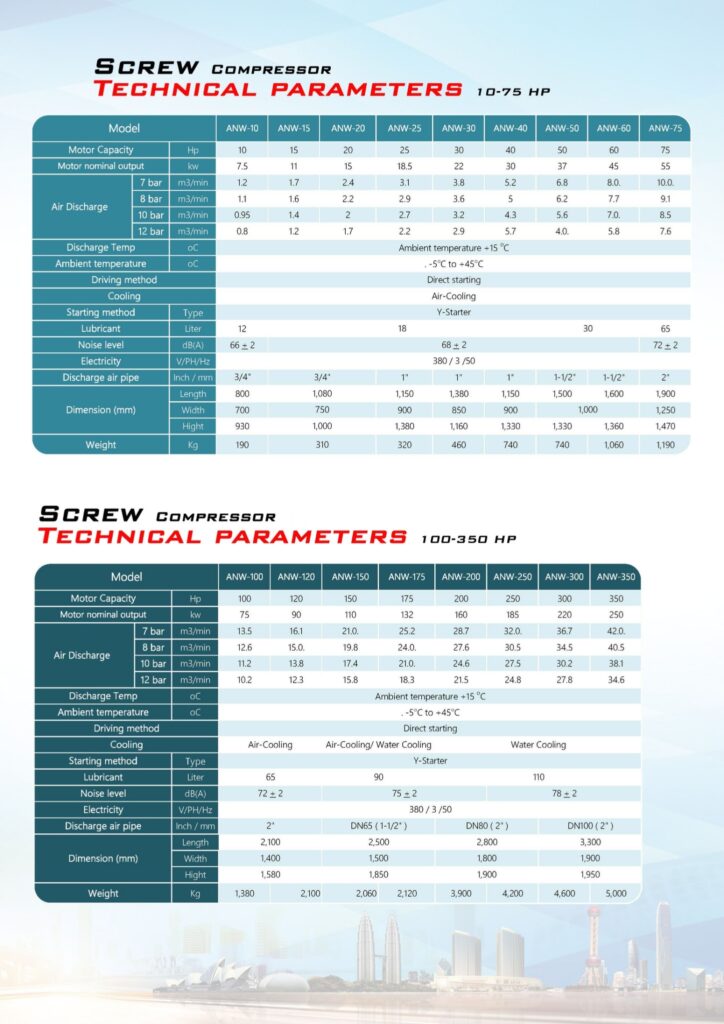

VSD achieves cost saving by ideal air capacity control. AIRCOMP inverter controlling system brings about larger capacity under lower pressure or higher pressure under smaller capacity. The operable pressure range is from 0.44 to 1.0MPa*, and air capacity is increasing maximum 6-14% compared with conventional models. (*In case of 50 HP /37kW model)

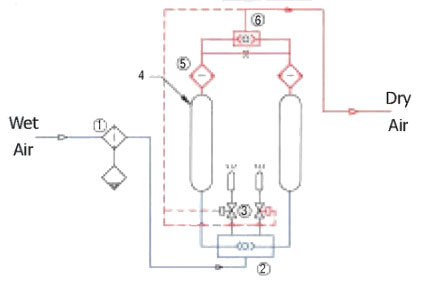

Heatless air dryer is composed of two alternate tower,one set of switching valves and one set of controlling system, In the swiching time, one tower is adsorbing while the other one is regenerating Efficiency, Dew point -70 -C.

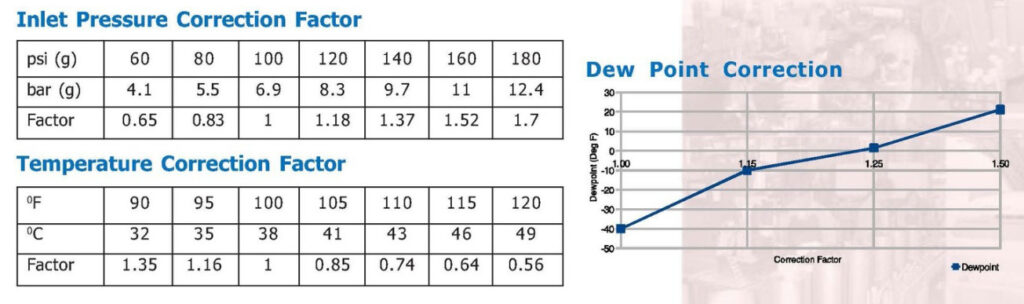

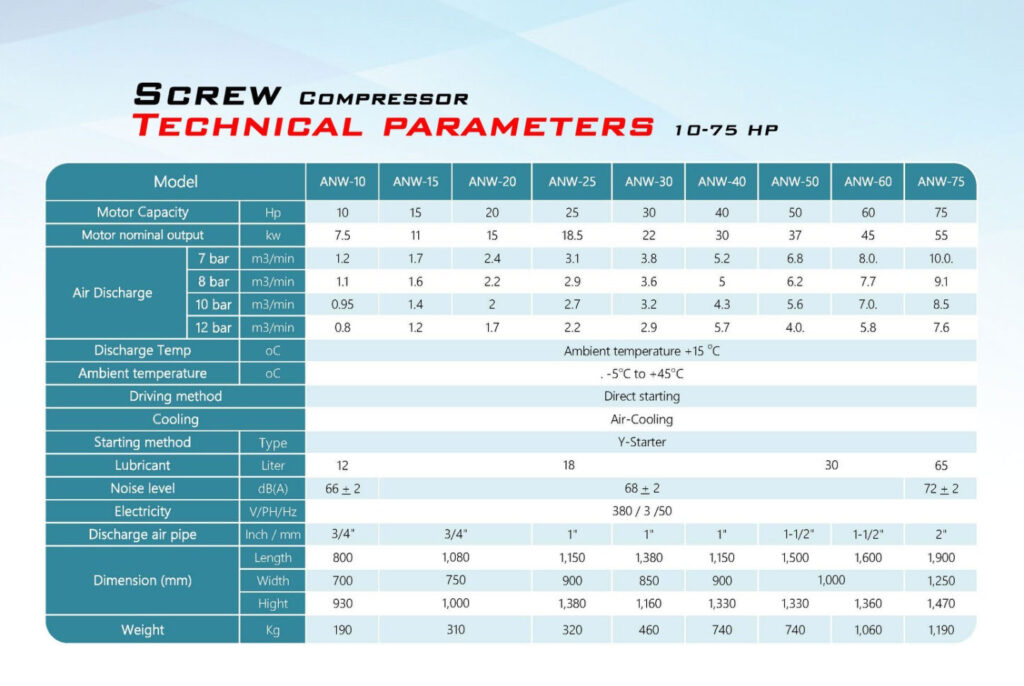

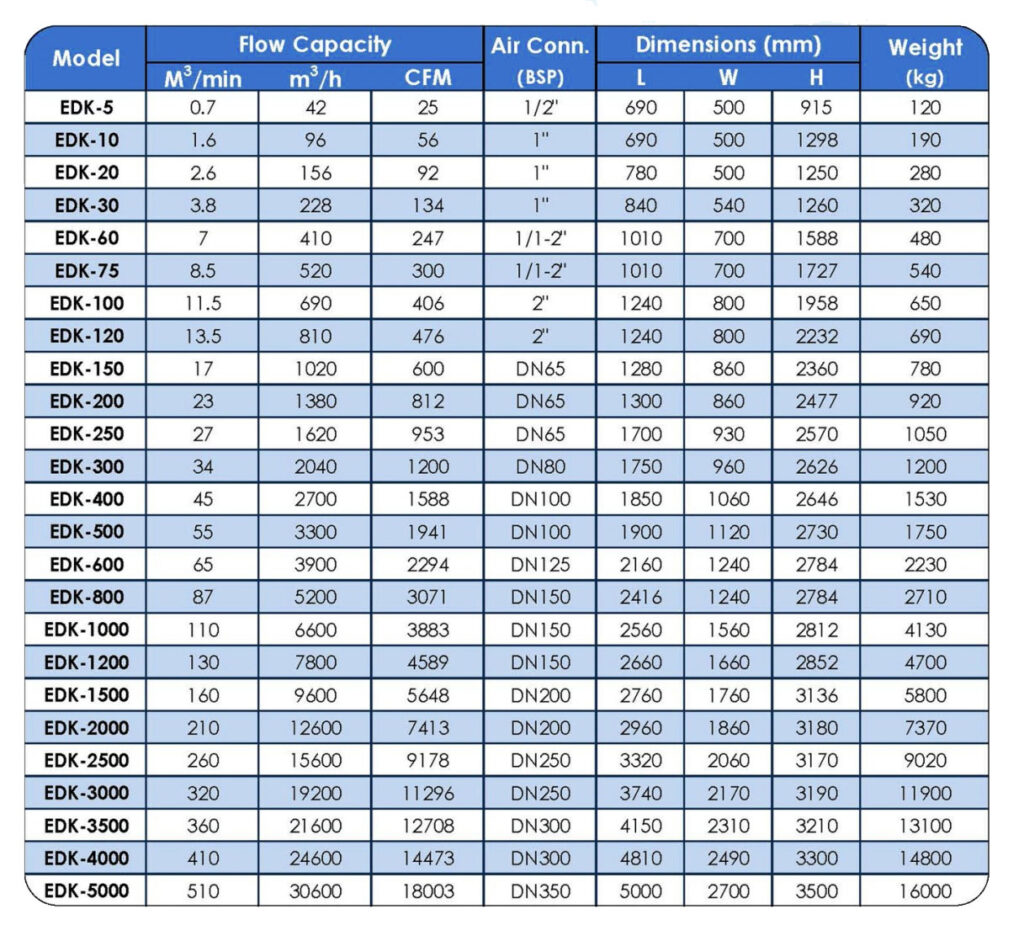

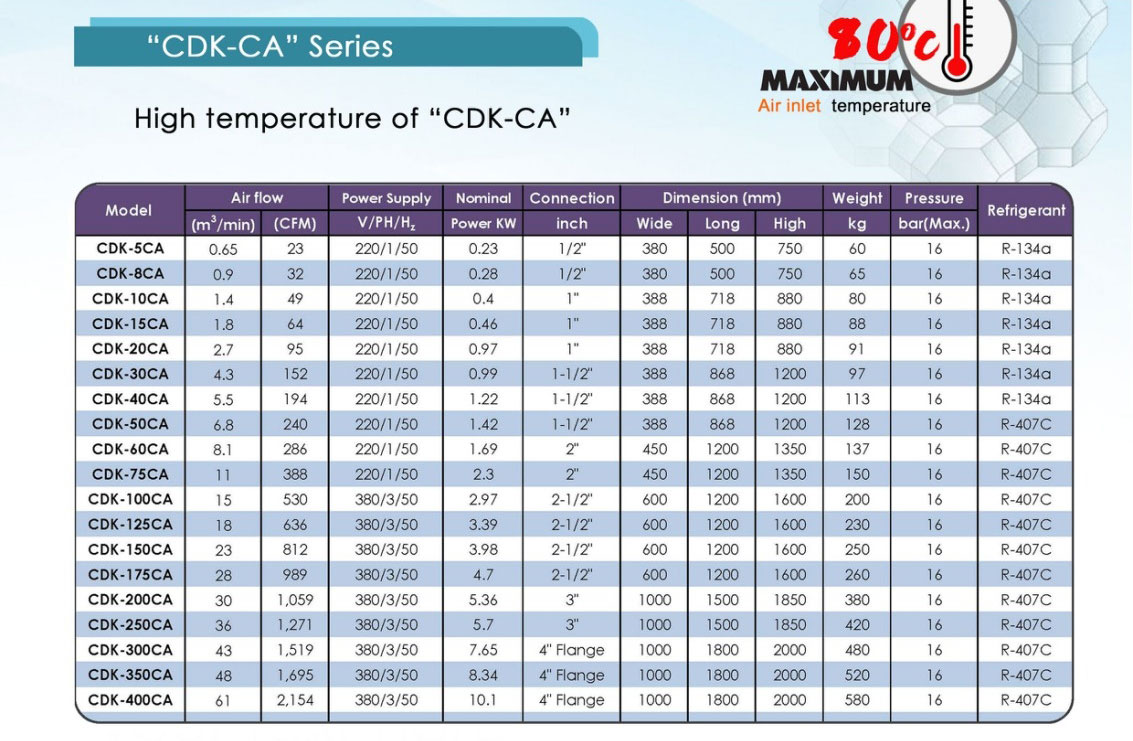

Specifications

Our Primary Product Lines

- After Cooler

- Refrigerant Air Dryer

- Desiccant Dry Spell

High technology Air Cooled After Cooler

Max. inlet Temperature 90 °C

Inlet & Outlet for Model : DAC 015-075

Inlet for Model : DAC 150

Outlet for Model : DAC 150

Inlet & Outlet for Model : DAC 250-400

CAPACITY : 18 – 36 M3/min

AIR CONNECTION : 1″- 3″

MAX.WORKING PRESSURE 16 bar

FLOW RATE REFERS TO

: Inlet temp 99C

: Ambient 359C

: Outlet of Ambient Temp + 10

Technical Specification of DAC Series Air Cooled After Cooler

HIGH TEMPERATURE * HEAVY LOAD* FULL LOAD truly meet the need of your

air dryness Air quality requirements ISO-8573. 1

– Independent large after-cooler design,cooling capacity increase 10% to 20 %,suitable for high- temperature and heavy-duty use.

– Using Energy Design – an independent after-cooler set cooling inlet air , firstly can remove the moisture content 30% to 50%, dramatically reducing the cooling load on the system could save up to 20 – 30 %

– Air Qutlet warmed by the heat exchanger, to prevent the rear air pressure system condensation and corrosion within the pipeline, to ensure compressed air system is clean and reliable.

– All machines designed meet CE safety requirement, using electrical components with CE safety certication. Compact Desing, configuration, save installation space.

– Using high temperature powder coating paint casing, beautiful and do not rust

– Fully closed base with Galvanized anti-corrosion design

Dryspell Plus Desiccant Dryer offers total cleaning solution for lubricated as well as non-lubricated compressed Air.

1. Pre-filter

2. Inlet shuttle valve

3. Exhaust valve

4. Desiccant tower

5. After filter

6. Outlet shuttle valve

Application

– Painting And Powder Coating

– Machine Tool

– Packaging Application

– Auto Garage

– Textile & Garment

– Instrumentation Pharmaceutical

– Dental Laboratory

– Rail Vehicles

– Telecomm industry (pressurizes its underground cables to repel moisture and avoid shorts)

– Pneumatic control systems

– Feed air for Zeolite type Oxygen and Nitrogen generators

– Truck and Train Air brake systems.

Market Acceptance

– Excellent Performance

– High Reliability

– Require Less Service Time

– Very Reasonable Cost

– Low moving components

– Low Maintenance

– Very Safe Operation

– Global Support

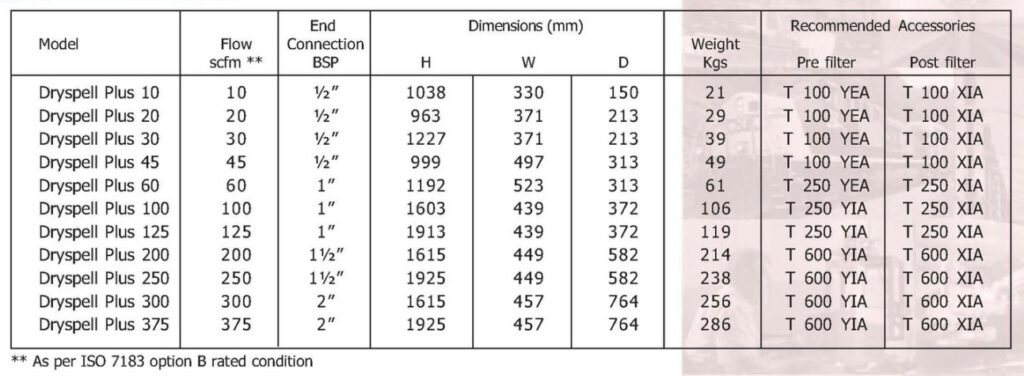

Specifications

Maximum Operating Pressure: 16 kg/cm2(g)

Air Inlet Temperature : 38 °C Max

Operating Pressure : 7 kg/cm2(g)

Pre-Filter Rating : 0.01 Micron

Cycle Time : 4 Minutes

Operating Voltage : 100-240 VAC 50/60 Hz 1 Ph

Outlet Conditions : Dry air at -400C PDP*

Purge Loss :15+1%

* ISO:8573-1:2010(E) class -2-