Start Button: Press this button to start the compressor.

Thank you very much for choosing and using our screw air compressor manufactured by the company. Please read the user’s manual carefully before operating the machine. Our screw compressor is a two-shatt positive displacement rotating type air compressor with alternate name of two-shaft air compressor. The compressor has high and reliabl operation characteristics, high gas transmission efficiency characteristics, excellent dynamic balance characteristics, low noise and vibration as well as easy operation and maintenance. It is of long performance life and environment protection. Commonly used in industries of precision machinery and instruments, electronic products and food, Chemical Fiber and Textile, aerospace application chemistry, decorative coating, medical pharmaceutical, traffic transportation and ag Products have a universally acknowledged development prospects.

The screw compressor manufactured by the company is an achievement of several years’ research and development. The combination of these prerequisite conditions guarantees a long performance life, high reliability and operational efficiency. The products meet all requirements for environment protection.

The machines and units of the series are manufactured according to mature technology and recognized safety rules. The occurrence of the following, however, might cause threat to the user or life and body of the third party, which might cause damage to the machines and other material possessions- Incorrect range of application

– Operation by unqualified personnel

– Unreasonable modification or transform to the machines

– Nonobservance to safety rules

As a result, all staff that has the right to operate, maintain or repair the machines has to read and obey all safety rules. It can be confirmed by signature if necessary.

Besides, the following shall also be obeyed:

– Relevant accident prevention rules

– Acknowledged safety rules

– National laws and regulations.

The machines and units of the series must be operated in perfect technical conditions and must be operated compliance with the range of application and guideline specified in the operation manual. The operators shall have strong safety awareness and fully recognize the risks during the operation of the machines. Any functional breakdowns, especially those that will threaten the safety, must be repaired in time.

The machines must the carefully maintained to meet various requirements for screw com-pressors or compressor units. The machines, therefore. must be carefully maintained during the specified maintenance period, especially in condition of bad working environment.

Guarantee

Get wise to the machine as well as relevant introductions before operating the machine. If the operation of the machine is inconsistent with the range of application or intended use goes beyond the range mentioned in the manual, the company will not be responsible for safety of the operation.

In following conditions, warranty claim will not be accepted by my company:

Maloperation

o Improper maintenance

o Misuse of auxiliary materials

Nonuse of the original parts manufactured by my company

o Modifying or repairing the equipment

Safety rules

Safety rules in the operation guideline shall be strictly abided by.

Technical modification

We reserve the right to modify the parts without prior notification during the process of technical research and development.

Note: If you have any demand, please contact with the local service provider of my company at any time, we will provide more excellent service for you.

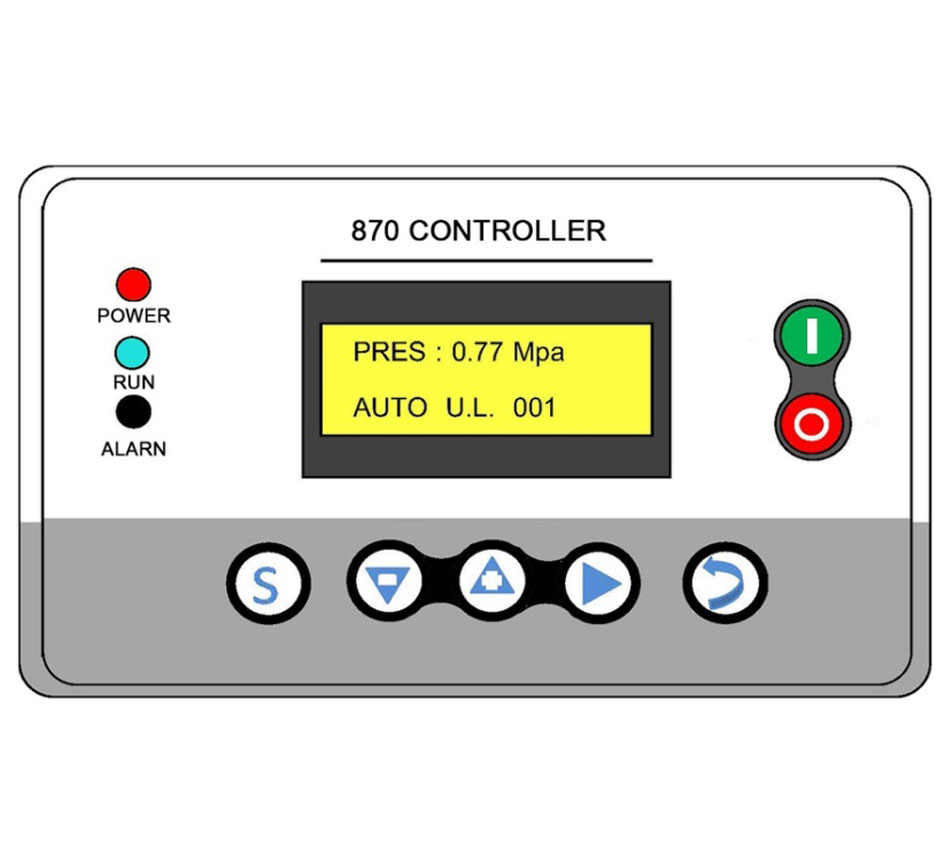

Start Button: Press this button to start the compressor.

Stop button: Press this button to stop the compressor.

Set Button/ Loading / unloading Button: After modification, press this to confirm andsave modified data; When the compressor is running ,press this button to load orunload under a certain pressure.

Move up button/increase button: Data at current position is increased by pressing this button when data are modified; Menu is moved upwards when menu is selected.

Move down button / Descending button: Data at current position is descended by pressing this button when data are modified; menu is moved downwards when menu is selected.

Shift button /Enter button: This button services as shift button when data are modified and services as enter button when menu is selected.

Back button / Reset button: This button services as back button when operate menu to comne back Parent menu; resetting is carried out by pressing this button for a little long time when failure shutdowns